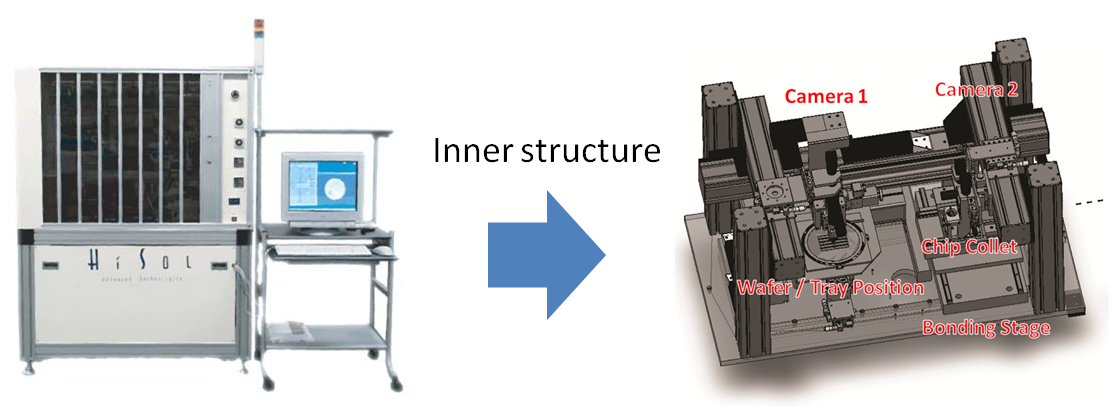

Automatic Flip Chip Bonder M-400

wafer handling (with trays), flip chip and image processing, alignment, thermo-compression bonding, adhesive bonding (with a dispenser, etc.), and eutectic solder bonding.

Highest-grade automatic flip chip bonder with the alignment accuracy of ±5 microns

Features

- Most suitable for manufacturing a wide variety of products in small quantities and for trial development because conversion kit can be easily changed.

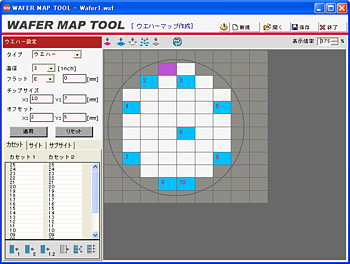

- Allows packaging of 4 to 8-inch wafers (including broken or chipped wafers) under PC software control.

- Available with various optional parts, including a pyramid collet, a pulse heater, a scriber and a stamper.

- Can be customized to best satisfy user needs in terms of layout, budget, functions, etc.

- Offered as the only one of its kind system in the world.

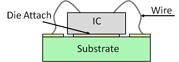

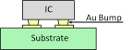

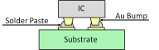

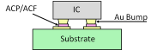

Compatibility of this system with various bonding methods

Data varies depending on materials used.

For details, refer to data provided by material manufacturers.

System specifications

| Model | Automatic flip bonder M400 α | Automatic chip transfer device M400TR |

|---|---|---|

| Function | Fully automatic bonding or manual alignment by jogging | Fully automatic transfer of wafers onto the chip tray, the adhesive tray and the dedicated system tray, etc. |

| Alignment accuracy | ±5.0μm | ±10μm |

| Applied load | 50-1000g | 50-1000g |

| Alignment | Automatic | Automatic |

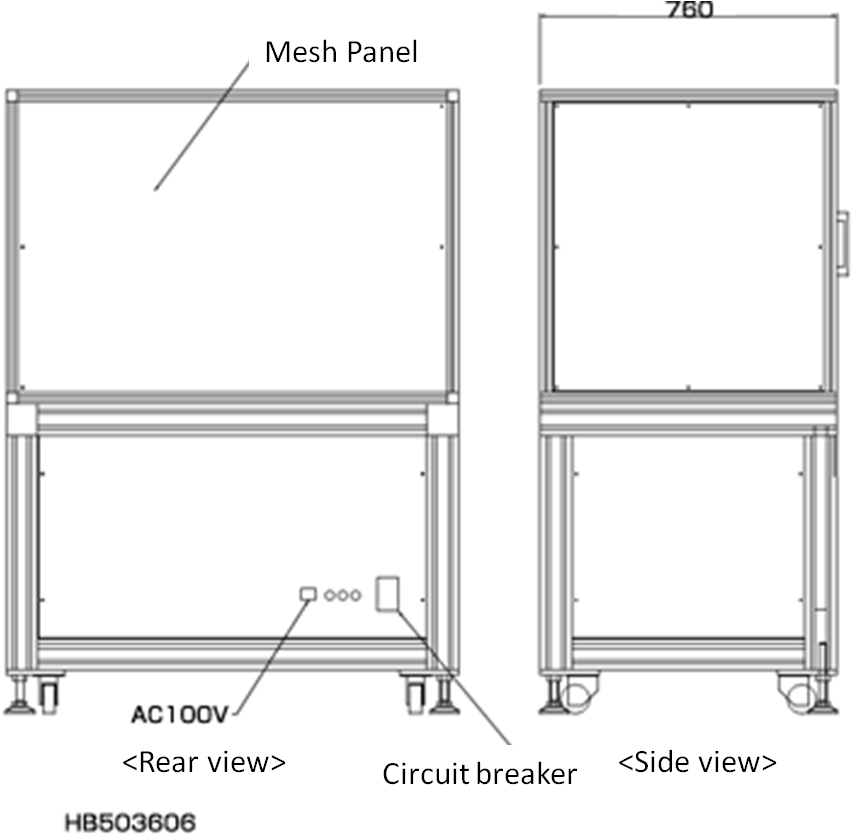

System dimensions

Optional parts

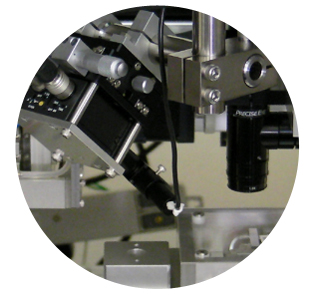

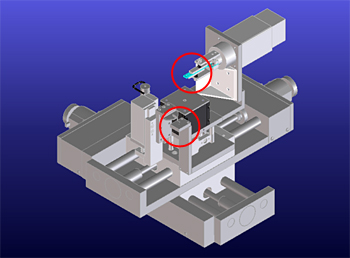

Pulse heater bonding stage

and packaging monitor camera

Continuity test probe stage

and flip-chip unit

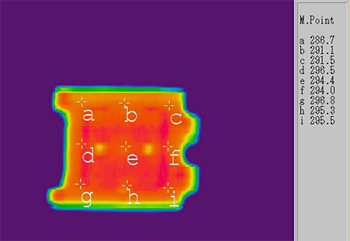

20 × 20 mm pulse heater head

Surface temperature distribution at 295°C

Pickup by wafer mapping